Convenient and fast mold counter status readings from your production floor.

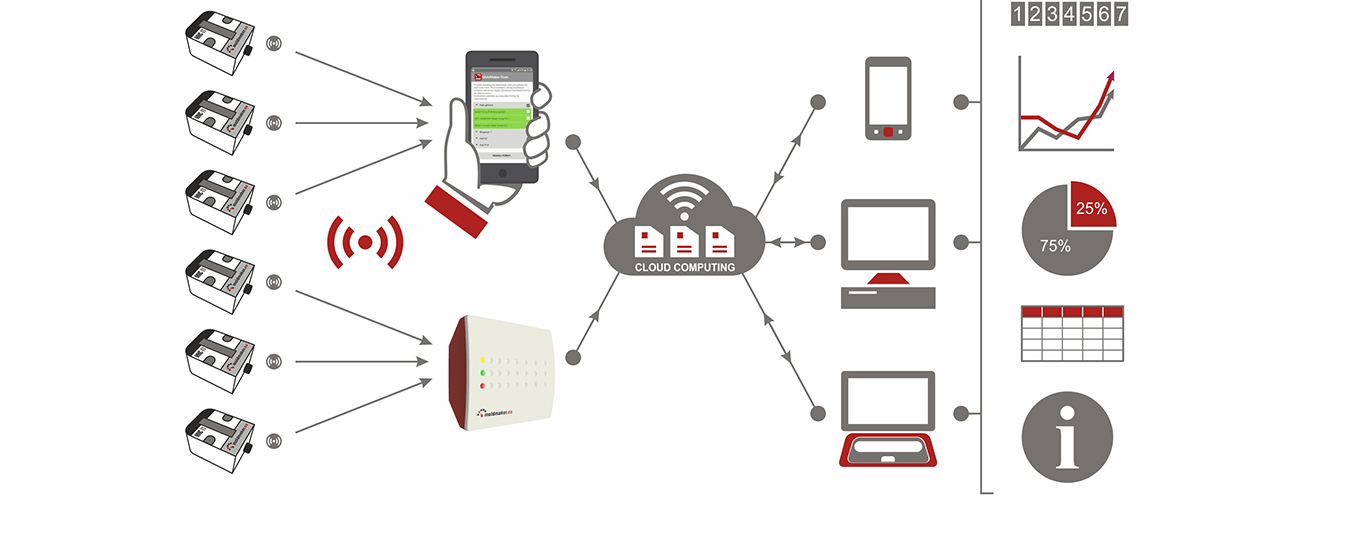

Pattented and innovative technical solution. The mould counter is made of PA6GF15 plastic, 8-digit display protected by a PMMA front panel, a cycle button and a disassembly button. The counter’s geometry and the spacing of the mounting bolts are consistent with the dimensions of mechanical counters for molds. It is fully interchangeable with old mechanical mould counters. An interesting fact is disassembly button, which protects against unauthorized unscrewing the counter out of the tool. In this situation, a disassembly notification is generated. The device has a built-in transmitter which emits the current value of the counter and other control signals, which can be received in two ways: using the Android phone with MoldMarker Scan application installed or using the MMCD Concentrator. The counter is also equipped with an NFC module, which enables bidirectional communication using a phone with the MoldMaker Scan application. The physical operation of the transmitter works by sending periodically very short digital pulses. The radio signal is preferably reflected from various surfaces, propagating in multiple directions.

The MoldMaker system enables data collection from counters connected to injection molds. Remote viewing of working tools located in a distant location. Statistics and performance graphs. Register of technical inspections, service reminders, etc …

Bluetooth and NFC connected interface

Connect using our mobile application

or a concentrator hub

wireless and non-resettable

average scanning range 30-120m (100-400ft )

it only counts forward, no reset available

disassembly notification

receive a notification in case of unauthorized unscrewing

keeps a record of any unauthorized disassembly

simultaneous scanning of several hundred counters in the hall

regardless of the number of counters you have connected,

scanning only takes several seconds

5 years

battery life

max work temperature 85°C, 125°C, 150°C, 205°C ( 185°F, 250°F, 300°F, 400°F).

records inventory of your tools

record, list of important plastics,

injection machines, and names of tool engineers amongst others

documentation management of

service cards, checklists,

maintenance schedules, Tool Cards

tool efficiency charts

automatically generates detailed efficiency charts

Download our application onto any Android-enabled tablet

or smartphone with Bluetooth or NFC capabilities.

With the app you can scan counters, send tool data

directly to your MoldMaker Enterprise software account, accept new tools into your

inventory, adjust configurations, perform Tool Card readings and add service notes.

Another great feature is the ability to rotate the LCD display,

allowing a counter to be mounted “upside down”.

This the heart of the MoldMaker system.

It allows you to manage your inventory of injection tools, edit parameters, set reminders for inspections, print Tool Cards view and service reports, view graphs of performance and activity of injection tools.

| COUNTER VERSION | MMC 11 MINI | MMC 11 STANDARD | MMC 11 HT | MMC 12 HT | MMC 12 UHT | MMC24 |

|---|---|---|---|---|---|---|

| 8-digit LCD display |  |  |  | |||

| Tool tag |  |  |  |  |  |  |

| Wireless scanning (BT) |  |  |  |  |  |  |

| Proximity reading ( NFC ) |  |  |  |  |  |  |

| Full package of MoldMaker features available |  |  |  |  |  | |

| Compatibility with MMCD Concentrators |  |  |  |  |  | |

| Temperature resistance up to 85ºC (185ºF) |  |  |  |  |  |  |

| Temperature resistance up to 125ºC (257ºF) |  |  |  | |||

| Temperature resistance up to 150ºC (300ºF) |  |  | ||||

| Temperature resistance up to 205ºC (400ºF) |  | |||||

| Disassembly button |  |  |  |  | ||

| Handling of presses and injection machines |  |

| Temperature resistance | |

|---|---|

| Counter MMC-11 MINI | 85ºC (185ºF) |

| Counter MMC-11 standard | 85ºC (185ºF) |

| Counter MMC-11 HT (High Temperature) | 125ºC (250ºF) |

| Counter MMC-12 HT (High Temperature) | 150ºC (300ºF) |

| Counter MMC-12 UHT (Ultra High Temperature) | 205ºC (400ºF) ! |

| Counter MMC-24 | 85ºC (185ºF) |

| MoldMaker Scan mobile application - free | - |

| MoldMaker MMCD Concentrator (LAN version) | - |

| MoldMaker MMCD Concentrator (GSM version) | - |

| PRICE | |

|---|---|

| Standard functionality | free |

| Advanced functionality | Prepaid fee

or subscription contract |

| Standard functionality ( free) | Advanced functionality | |

|---|---|---|

| Wireless scanning over 30m |  (every 5 min) |  (every 30 min) |

| Proximity reading |  |  |

| Tool Specification Card |  |  |

| Maintenance Schedules | - |  |

| Maintenance Cards | - |  |

| Tool efficiency calculations |  |  |

| Counter disassembly status |  |  |

| Spare parts register | - |  |

| Service Jobs register | - |  |

| Alarm and monitoring of counter disassembly | - |  |

| Tool status |  |  |

| Counter signal level status |  |  |

| Show "SERVICE" notification on LCD display | - |  |

| Tool sharing | - |  |

Use Virtual Advisor for a preliminary devices selection:

This optional receiving device requires no maintinence, operates automatically, regularly collects readings from counters that are in range and sends the data to the moldmaker.eu enterprise platform. For coverage in very large production halls, you can install and sync more than one concentrator.

It also serves as security in the event of a lack of internet connection with the server. Stores readings in its internal memory, and after obtaining an internet connection, transmits the collected data to the service thus maintaining the continuity of work.

Data from counters to the moldmaker.eu enterprise internet platform is sent out every five minutes. The MMCD Concentrator is a useful and convenient addition to the MoldMaker Scan application. However, unlike the mobile app which requires the user to send and request data from coutners on demand, the concentrator does it automatically in consistent five minute intervals.

The MoldMaker Scan application also has NFC configuration functionality available such as, preview of mold parameters, reading service reports, schedule configuration, etc.

MMCD concentrators are used by companies that have many injection molds, where the speed and regularity of collecting data from working tools is especially important. The concentrator is usually mounted on a ceiling or wall, away from metal elements and devices that could interfere with its operation, such as WiFi routers, switched-mode power supplies, and lamps. The MMCD concentrator should be installed in a location that will offer the best working conditions and also cover the largest possible area. The concentrator connects to the internet using a LAN cable or GSM router. The device does not connect to the internet over Wi-Fi. If you require coverage for a very large area, you easily sync more than one concentrator together to cover more space.

This is a new era in the fast and convenient reading of molud counters!

The MoldMaker system is a technological solution intended for small, medium and large business involved in the processing of plastics. It is used for wireless reading of mold counters installed on injection molds, providing a live overview of production progress on molds.

The idea of the system is based off a few simple concepts:

MoldMaker is an enterprise solution that can help large companies monitor progress and efficiency in their factories. With MoldMaker, you can view data for an individual factory as well as your entire portfolio in one place. The MoldMaker system can also be used for remote monitoring of subcontractors who perform production on received tools. As a precautionary measure, the system can detect if a counter is disassembled from the tool and the mechanical blocking of the cycle button. In the event of blocking or disassassembly the owner will recive an automatically generated warning notification.

The MoldMaker is also a great tool for small businesses. Even if a company only has a few injection molding machines, MoldMaker is useful because it facilitates convenient reading of the counters in the hall, easy to read visual data about tools or cycle times and for ordering operations related to inspection and mold servicing.

In order to use the MoldMaker system, first, install the MMC-11 counters on your injection tools. Then, register your company account on our online service, moldmaker.eu. You can have multiple users across your company using one account. In the case of large corporations, each individual company under the umbrella of a single corporation must set up its own account. However, the corporation can supervise all of its companies within the moldmarker.eu online system.

The Tool Cards, mentioned above, available in the system are detailed documents describing the structure and technical parameters of the tools held. They can be used for various purposes related to operating, manufacturing and designing new tools. Service notes and reminder schedules are tools to facilitate the timely management of injection tools from the side of inspections, repairs, periodic or planned activities. They provide a detailed history of the activities performed.

System components: